Mun san cewa za mu bunƙasa ne kawai idan za mu iya tabbatar da haɗin gwiwar farashin siyarwa da inganci mai kyau a lokaci guda don hatimin harsashi na CURC ga masana'antar ruwa. Muna maraba da ku da ku tambaye mu ta hanyar kira ko wasiƙa kawai kuma muna fatan haɓaka haɗin gwiwa mai wadata da haɗin gwiwa.

Mun san cewa za mu ci gaba ne kawai idan za mu iya tabbatar da haɗin gwiwar farashin siyarwarmu da kuma ingancinmu mai kyau a lokaci guda, don haka, farashi mai gasa, kunshin da ya dace da isarwa akan lokaci za a iya tabbatar da shi bisa ga buƙatun abokan ciniki. Muna fatan gina dangantaka ta kasuwanci da ku bisa ga fa'ida da riba a nan gaba kaɗan. Barka da zuwa tuntuɓar mu da kuma zama masu haɗin gwiwarmu kai tsaye.

SHARUDDAN AIKI:

ZAFI: -20℃zuwa +210 ℃

MATSI: ≦ 2.5MPa

SAURI: ≦15M/S

Kayan aiki:

Zoben SATIONARY: MATAKI/ SIC/ TC

Zoben ROTARY: MATAKI/ SIC/ TC

HATIMIN BIYU: VITON/ EPDM/ AFLAS/ KALREZ

SASHE NA BAƘI DA ƘARFE: SS/ HC

AIKACE-AIKACE:

RUWAN TSAFTA,

RUWAN WEWAGE,

MAN FETUR DA SAURAN RUWA MAI TSABTA MAI TSATSA.

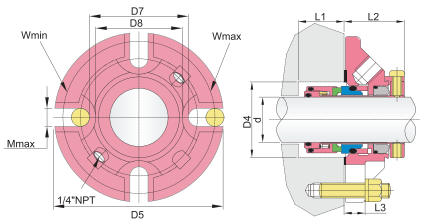

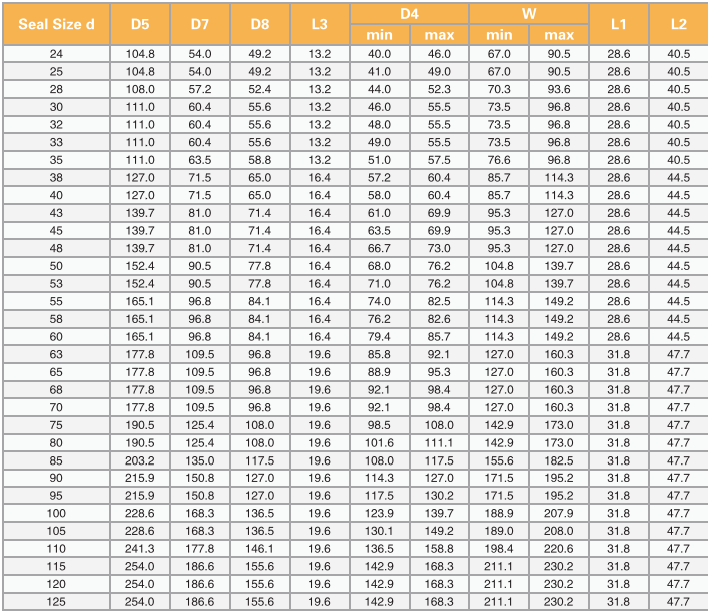

Takardar bayanai ta WCURC na girma (mm)

Fa'idodin Hatimin Injin Kwalta Nau'in Kwalta

Manyan fa'idodin zaɓar hatimin harsashi don tsarin hatimin famfo ɗinku sun haɗa da:

- Sauƙi/Sauƙi shigarwa (Ba sai an buƙata ƙwararre ba)

- Tsaro mai ƙarfi saboda hatimin da aka riga aka haɗa tare da saitunan axial na gyara. Kawar da kurakuran aunawa.

- Ya kawar da yiwuwar ɓatar da wuri da kuma matsalolin aikin hatimi da suka haifar

- Rigakafin shigar da datti ko lalata fuskokin hatimin

- Rage farashin shigarwa ta hanyar rage lokacin shigarwa = Rage lokutan aiki yayin gyara

- Yiwuwar rage matakin wargaza famfo don maye gurbin hatimi

- Ana iya gyara na'urorin harsashi cikin sauƙi

- Kariyar shaft ɗin abokin ciniki / hannun riga

- Babu buƙatar sandunan da aka yi musamman don yin aiki da hatimin da ya dace saboda hannun riga na ciki na harsashin hatimin.

hatimin injin harsashi don famfon ruwa